The problem with this set up is the RF card, which some employees don't bother to return, when they don't bother showing up to work anymore. Each RF card costs P20, and the scrooge in me throws a tantrum everytime an employee decides to go AWOL with the card. The scrooge feels worse for the unreturned card than the employee not reporting to work. Weird.

Regular employees can decide to just go AWOL like they were just cancelling a scheduled dinner, so much so new, probationary employees, who virtually have no commitment whatsoever to the company just yet, since they're still on probation. So it has become my practice not to use the finger scanning device for their attendance just yet as well, because the RF cards are my precious.

Previous practice was they used a time card for their records. However, there was a time we had 20 new employees. And encoding the times for 20 people is not pleasant work for the person typing all that, the same person who has other things to do.

So I wrote Mila, named after my MBA economics professor.

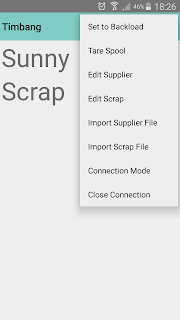

Mila is a bundy clock Android app that reads an employee's NFC, and records his/her time in a CSV file. The app also includes a registration function, which writes employee information in an NFC card for identification when the card is tapped on to the device.

Everyday, I just download the CSV file to know if a new employee is present or absent. At the end of the week, the attendance file is passed to a program that computes the payroll. The staff is freed from manual transfer of time card data to the computer, which enables the staff to do other value added activities.

And to solve the problem of employees not giving back the card in case they go AWOL, I don't let them bring the NFC cards home. Just like time cards, the NFC cards are left on the desk of the security guard, so they only use it when they need it. And the phone that has Mila in it is managed by the guard, who personally taps the NFC on the phone to ensure that the NFC card is indeed assigned to the person.

To register an NFC card to an employee, tap the "Add Contact" icon on the upper right.

The "Add Employee" screen appears. Fill up the information required, and tap the NFC card close to the device. A message will appear when registration is successful.

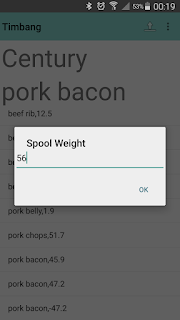

To record time in or out, tap the button (Clock In, Clock Out) of the applicable time status. Then tap the NFC card close to the device. The employee record appears on the main screen, and his/her time record is written to the CSV file log.csv.

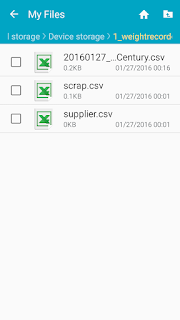

log.csv can be viewed at internal memory's 3_mila directory.